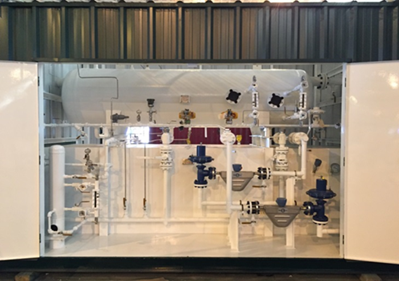

Provided all fabrication, installation and pressure testing, including labor, materials, equipment, and manpower.

Provided all fabrication, installation and pressure testing, including labor, materials, equipment, and manpower.

Turnkey Project- land clearing, fabrication, install and testing. Supplied all equipment and manpower.

Fabrication, Inspection, and Testing of a GPU Pressure Vessel, Line Heater and Coils, and On Skid Piping. All process piping welds follow B31.3 specification.

Fabrication of 1000's of pipe spools and configurations ranging in size from 4”to 60” diameter and up to 50' long, each with multiple and varied flanges, tees, elbows, reducers, etc. Met critical deadlines over many months.

Although NuWeld, Inc. no longer works in the nuclear industry, in this previous project, we constructed over 10 “Mating Devices” used in fuel to cask transfer activities for various power plants around the world.

Although NuWeld, Inc. no longer works in the nuclear industry, in this previous project, we fabricated more than 70 units of MAP 12 Fresh Fuel Shipping Containers and Over the road containers used for transporting Fresh Fuel Rods. Each unit contained over 300 meticulously fabricated stainless and duplex steel parts welded into approximately 12’ long finished products.

Stainless steel & titanium bent/welded pipe "joggles" for Hanford, comprising unsleeved, sleeved and sleeved w/insulation configurations. Price Anderson Act of 1988 including 10 CFR Part 830, subpart A.